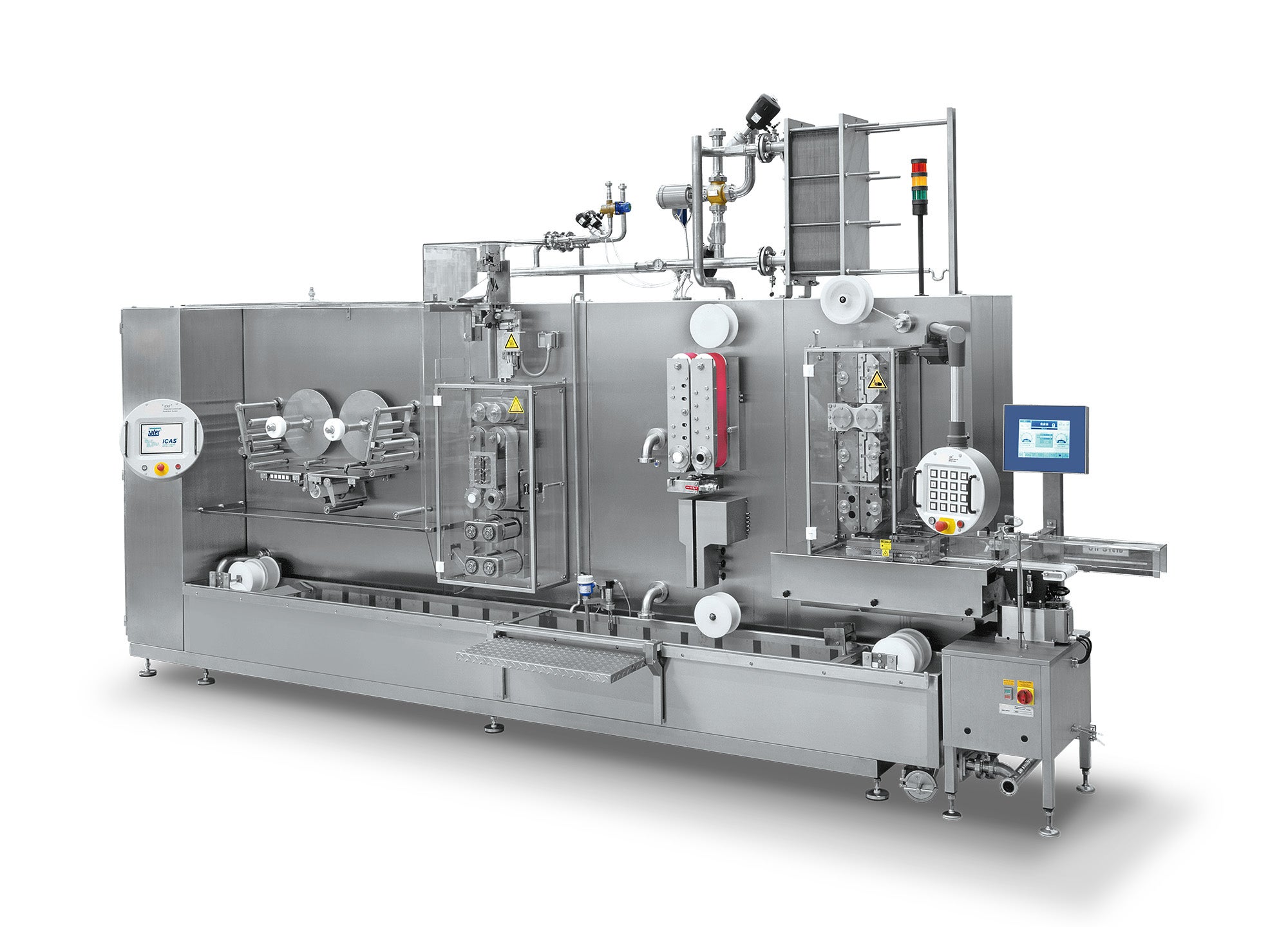

The Natec FreePack produces individually wrapped processed cheese slices (IWS) through a continuously operating production method.

The Natec FreePack produces individually wrapped processed cheese slices (IWS) through a continuously operating production method.

Wrapping is performed without risk of contamination using the hot-fill system. The poly-propylene foil used is environmentally friendly and recyclable.

Exact sealing ensures the product to be securely wrapped and sealed, while the individually wrapped slices are easy to open.

They are of exactly uniform weight and accurately stacked in piles, which remain in exact position during transport from the FreePack to the Flowpacker.

The FreePack will offer you minimised operation costs thanks to its low film consumption (10% reduction due to small and efficient welding seams), high OEE and low utility consumption. Its ability to operate for one week’s production 24/6 with no cleaning also result in minimised costs for your business.

With servo drives for each sealing station, contact-free longitudinal sealing, a friction-free forming station, cross cutting system, low-wear sealing gear and easy parts changing, your FreePack is ensured to have minimum wear and tear.

Further benefits include:

- Maximum productivity and high weight accuracy

- Unique cutting and stacking technique, which arranges and coordinates IWS into exact piles

- High operator comfort and trouble-free production results from the central control and surveillance system

- Less giveaway thanks to a consistent weight by means of a constant controls system

The FreePack comes with the option to attach a dosing tank, an inkjet printer for marking words such as ‘open here’, a metal detector and an IWS Mixstacker. Cooling with ice water or glycol and different sealing patterns are also available.

Cooling water is hygienically pure and required at an operating temperature of approximately 3°C. The FreePack is equipped with an integrated secondary cooling circuit, including a heat exchanger and a circulating pump.

Natec’s FreePack 1000 can process 1000 IWS slices per minute, utilising compressed air and fresh water for cooling. It can package stacks of 3 – 25 slices, with a maximum stacking height of 75mm. The slice weight is infinitely adjustable from 13g – 30g depending on the cheese texture.

The FreePack is available in two other sizes:

- FreePack 500- Processes 500 slices per minute at 600kg/h.

- FreePack 2000- Processes 2,000 slices per minute at 2,400kg/h.

Let us know your IWS requirement by using the form. We look forward to hearing from you and sharing our knowledge on our ‘success generating food technology’.