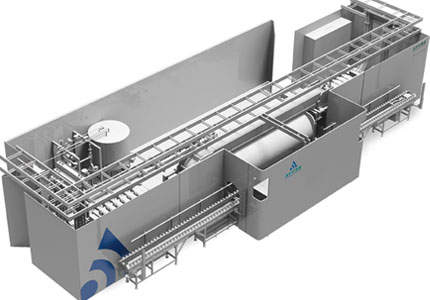

The Avure QFP 525L-600 measures up to the production needs of today’s high volume food processor, offering the highest throughput in the industry with features to minimize operating costs and maximize uptime.

The QFP 525L delivers the benefits of high pressure processing, handling up to 3,700kg (8,100lbs) of HPP product per hour – expanding capacity by at least 91% over our already efficient QFP 350L-600. Improved filling and pressurizing efficiencies, and a vessel diameter of 18.5in, result in higher throughput, larger volume, and ten cycles per hour with a 3min hold time. The larger diameter also accommodates processing of larger and odd-shaped product.

Footprint economy and enhanced safety

Despite higher capacity, the QFP 525L has a footprint as small as the QFP 350L. Safety features include alarmed systems for monitoring over-pressurization, alignment, elongation, interlocked doors, and a safety PLC for communication.

Ease of installation and maximum uptime

Installation of the QFP 525L is extremely fast, with a ‘sole’ securing the frame support structure to pre-located bolt-down points. Other components have been redesigned for efficient fill, ease of maintenance and replacement if necessary. As for all Avure HPP systems, our global support and maintenance maximize uptime for processors throughout the life of the 525L. An overall equipment efficiency (OEE) system facilitates fine-tuning of operation.