Bullant Creative Analytics and Change Management Services for Food Processing Factories and Supply Chains

Bullant Creative delivers analytics and change management services to companies within the food and beverage processing and packaging industries.

Clients usually enlist the company’s services in three key areas, namely crisis recovery, complex project management and supply chain improvements.

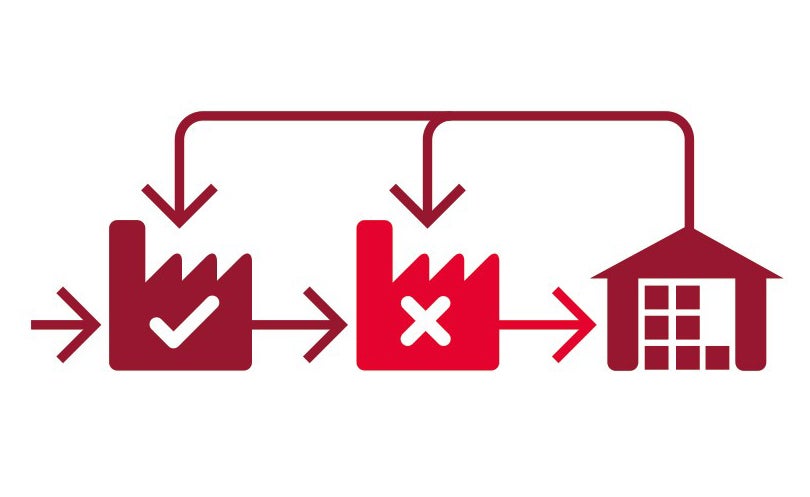

Tailor-made methodologies for integrating factories to supply networks

Integrating food processing factories into a broader supply chain can be challenging.

Bullant Creative has developed a tailor-made value stream mapping methodology that can be used to identify the current behaviour of a processing factory and show the opportunities for improvement as part of a future state.

The value stream map can be extended to identify opportunities in the broader supply network. This can be enhanced by network modelling.

Food and drink processing factory design and optimisation

Many of today’s improvement frameworks, such as Lean, are modelled on the car manufacturing industry.

Bullant Creative has dedicated ten years to developing tools and methodologies for process industries based on the latest industrial engineering science. These tools and techniques are used to identify and prioritise improvement opportunities in factory scheduling and efficiency.

These same techniques are used to convert ideas in a project business case into sound factory designs that deliver the necessary operational performance.

Modelling and monitoring of complex food production environments

Targets in complex production environments should be set as a result of robust modelling. High-technology systems behave in a consistent statistical manner and this behaviour can be understood and replicated using a model.

We model production and supply chain behaviour in a way that mimics reality. This confirms the accuracy of the model so that it can be used to design a better and realistic future state.

This type of validated model is often called a digital twin. A digital twin is used to identify the most important variables that must be monitored and improved to achieve a better future state. The digital twin is also used to show progress towards this future state by imputing the monitored variables as they change.

Control tower design to monitor supply chain performance

The supply chain is made up of inventory buffers, time buffers and capacity buffers. The performance of a supply chain in terms of customer performance and total cost to serve is determined by how these buffers are designed and how they interact.

Using a simple red-yellow-green traffic light system to represent the status of these buffers, a control tower can be designed to monitor the performance of all parts of a supply chain.

As every supply chain is different, each control panel will be tailor-made for each system, with the key concepts remaining the same.

Operations excellence targeting and performance-centred-improvements

There are many targets in a complex production environment. Operations personnel will tackle these as they arise. However, this can lead to overwhelmed resources, usually without a corresponding improvement in performance.

Bullant Creative has developed a way of assessing complex processing environments so that performance-centred improvements can be identified and prioritised. Valuable resources can then concentrate on what is important.

Supply chain analytics for operations strategy development

There are many working parts within a supply chain, particularly supply chains that are connected to complex processing factories.

While a lot of literature and tools are available for supply chains, there is a lack of information on how food processing factories can be developed to play their part in minimising the total cost to serve within a supply chain.

Bullant Creative applies analytics tools to different parts of the supply chain to diagnose how factories can be best developed to minimise inventories, enhance customer service and reduce costs.

Process and project design for food industry businesses

Converting a business case into a viable high-technology project scope can be difficult.

Having the experience and technical knowledge to be able to design complex processes is one thing, while being able to link that knowledge with the business case and negotiate different alternatives with business stakeholders is another matter.

Equipped with a unique set of skills, Bullant Creative concentrates on the complex jobs and is committed to providing clients with the support they need to make the crucial choices during project and process development.

About Bullant Creative

Based in Albury, Australia, Bullant Creative has provided services for well-known food processing companies such as Heinz and Fonterra for ten years.

The company provides senior supply chain and manufacturing executives in the food industry with a high-end resource that can:

- Decipher and explain the behaviour of complex factories and operating systems

- Simplify and design production platforms for complex product portfolios

- Prioritise and scope improvement activities on high-technology production platforms

- Provide high-end analytics, process engineering, operations and product management skills

- Empower and mentor client’s employees

- Provide new ideas and ways of working

- Deliver independence and experience

Please fill out the enquiry form for more information.

Products and Services

Video

White Papers

Related Projects

Press Release

Regional Offices

776 Forrest Hill Avenue

Albury NSW

2640 Australia