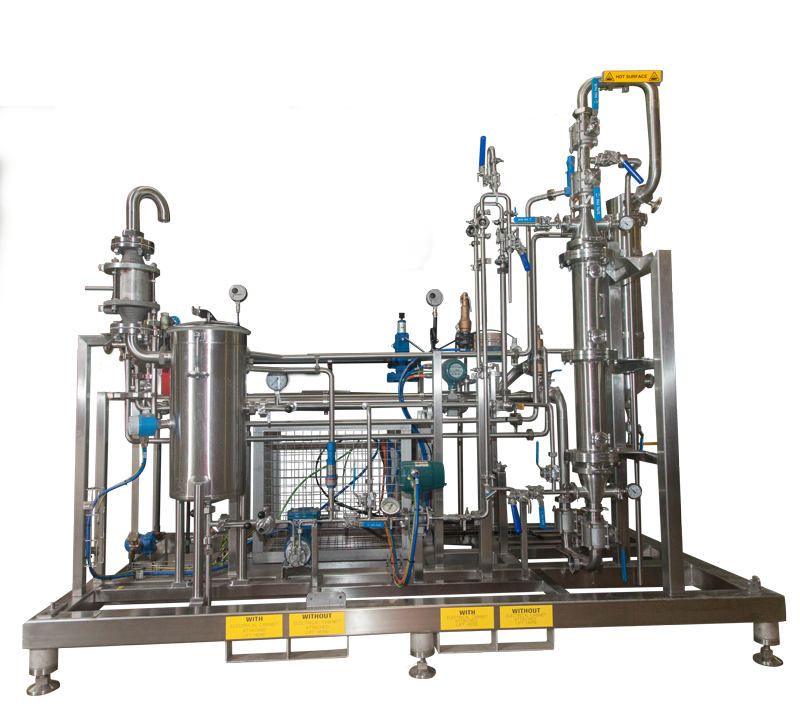

The new Flavourtech Resin Adsorbing Column (RAC) allows manufacturers of ‘0.0’% abv wine and beer-based beverages to recover and return aroma derived from the original product without any measureable increase in the final alcohol content. This allows for a more flavoursome product while avoiding the requirement to add, and potentially declare, external flavours on a product label.

Background

The Resin Adsorbing Column has at its core, the principles of adsorption and desorption. When using steam stripping, distillation or evaporation to remove alcohol from beer or wine, aroma compounds will inevitably also be removed with the alcohol.

Flavourtech’s Spinning Cone Column can be used to separate aroma from the bulk of the alcohol in the raw material such that the resulting alcoholic flavour can be added back to a de-alcoholised base. However, this alcoholic aroma still has the potential to add up to 0.4% abv to the finished product.

The ‘0.0%’ category demands a final alcohol concentration of <0.05% abv. The RAC system allows manufacturers to meet this requirement and produce a finished beverage that incorporates aroma recovered from the original feed material.

How it Works

The process consists of four stages:

- Adsorption: Alcoholic condensate recovered using the SCC and containing desirable aroma compounds is passed through a column containing a specially selected resin that ‘traps’ the aroma compounds (by adsorption) while allowing ethyl alcohol and water to pass through and be collected as a neutral, clean alcoholic by-product.

- Water Rinse: When the resin column is fully loaded with aroma a short water rinse ensures all ethyl alcohol is removed prior to desorption.

- Desorption: The aroma compounds are desorbed from the resin (without the

use of organic solvents) resulting in an aqueous based aroma that can be added back to the dealcoholised base. - Regeneration: The resin is regenerated prior to another operational cycle.

Contact Flavourtech via the enquiry form to find out more or to arrange a trial.