Global Water & Energy Group Turnkey Wastewater Treatment, Water Reuse and Green Energy Plants

GLOBAL WATER & ENERGY (GWE), a member of the Global Water Engineering Group of Companies, is an international provider of industrial wastewater treatment, water reuse, and green energy production solutions.

GWE offers state-of-the-art technologies to assist industries and private owners in their efforts to grow while reducing the costs of business.

From market-leading anaerobic wastewater treatment and organic waste-to-energy processes to a variety of premium aerobic systems, GWE has an extensive environmental solutions portfolio filled with leading treatment technologies.

Tailor-made solution for modern business problems

Global reach and a vast network of reliable partners are some of the reasons why GWE is the preferred supplier of many Forbes 500 companies, as well as medium and small firms operating around the world.

Unmatched performance standards and process guarantees contribute to GWE’s long-lived success. Sustainability has been at the heart of the GWE mission since the beginning of its activity. Now with almost 30 years of operational experience and innovation and over 160 employees around the world, GWE’s focus remains unchanged.

Turnkey industrial wastewater treatment plants for a plethora of applications

In addition to always offering an economically feasible solution, a comprehensive portfolio of technologies and decades of experience, GWE’s entire scope of services allows the company to deliver turnkey plants at virtually every location in the world.

Hundreds of processors of alcoholic and non-alcoholic beverages, starch, sugar, fruit and vegetable, dairy, fish and meat, mixed organic waste, pulp and paper, chemicals and petrochemicals reach superior plant performance and effluent quality while maintaining low energy and resource consumption with GWE assistance.

Reduce lifecycle costs and turn waste into profit with GWE

The optimal design of an industrial wastewater and waste management facility is decided upon by the GWE engineers to deliver the most cost-effective treatment that guarantees superior effluent and discharge quality.

This ensures that GWE’s systems and treatment facilities are an asset, not a burden, and a sustainable piece of the production puzzle for our clients and the surrounding communities.

GWE’s efforts and dedication to sustainability and excellence are recognised around the world. In 2019, the Institution of Chemical Engineers (IChemE) shortlisted GWE as a finalist in four categories of their annual IChemE Global Awards.

The distinction in Energy, Food and Drink, Sustainability, and Water categories shows that the GWE Group can solve the most complex environmental problems that many branches of industry are currently facing.

Benefit from often-overlooked energy potential of wastewater

Although the efficiency of the technological processes involved in the production of food and beverages has significantly increased throughout the years, industries in question still generate substantial volumes of wastewater, slurries, sludge, peels, and other solid residues.

The anaerobic treatment of wastes high in organic content generates high amounts of methane biogas, which can be burned on-site to produce heat and electricity.

With the millions worth of dollars saved on fossil fuels, decreased greenhouse gas emissions and reduced operating costs of the wastewater treatment plants, energy from waste resolves the two biggest challenges of modern industry: waste management and non-renewable fuel dependency.

Custom biogas valorisation systems for uninterrupted green energy supply

Biogas, as a carbon-neutral energy source, can feed steam and water boilers, combined heat and power (CHP) units, as well as biogas absorption units. For use without pre-treatment, GWE has developed the CALORIXTM Direct-fired Wastewater Heater, allowing customers to increase the wastewater temperature without expensive heat exchangers.

Continuous development and innovation within drying, desulphurisation and GWE’s direct wastewater heating systems guarantee the use of biogas as fuel at the lowest operating cost.

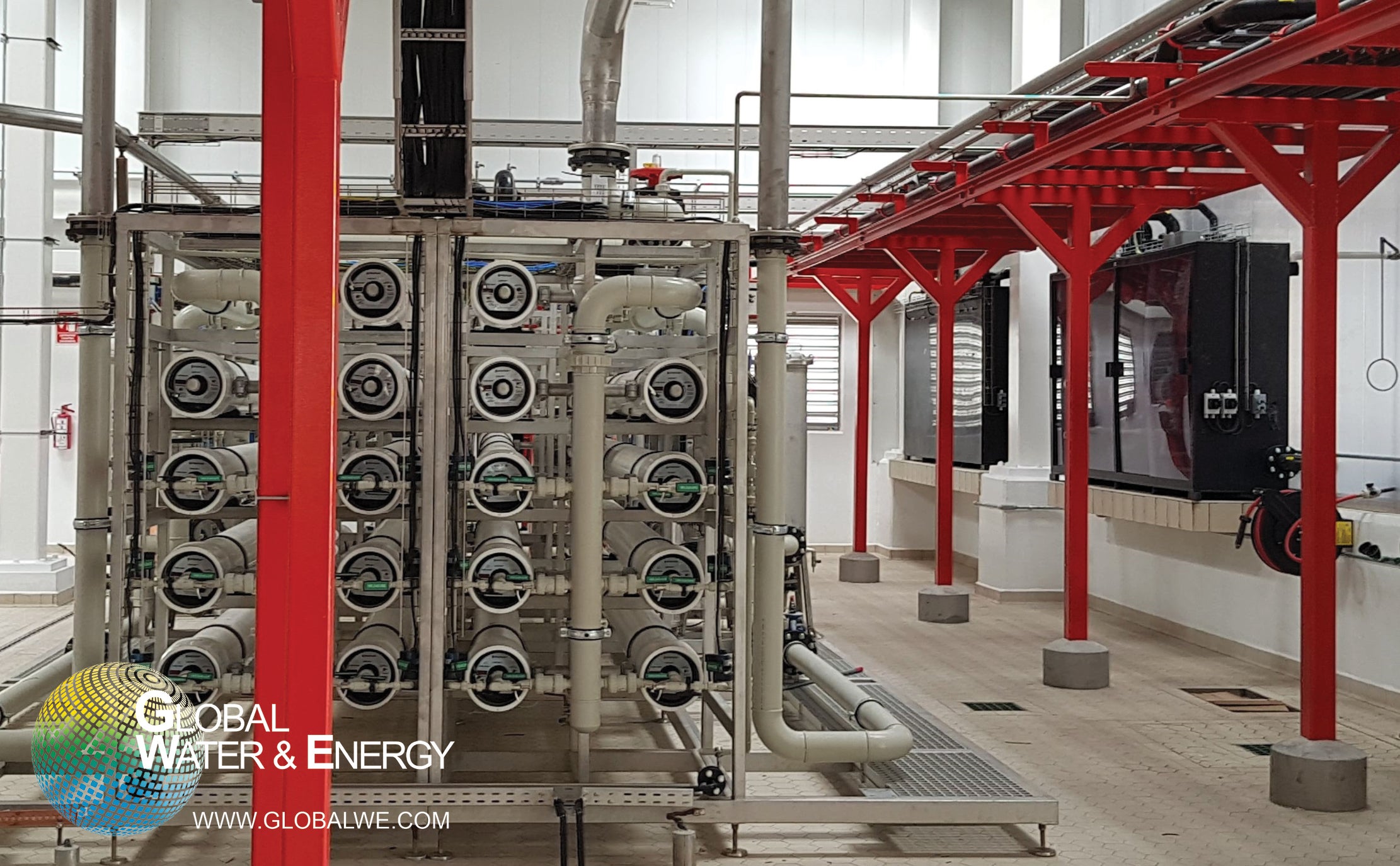

Water reclamation plants for high-quality process and cleaning water

GWE water reuse plants are custom-engineered installations that put in place multi-barrier systems to treat effluent from wastewater treatment plants. The tailor-made water recycling systems combine efficient pre-treatment and the latest membrane separation technologies to obtain high-purity water, guaranteeing a permanent source of water for production and cleaning.

The turnkey water reclamation plants, already installed at three major breweries, allow those facilities to reuse about 7,000m3 of post-production wastewater daily, equating to more than 2.5 million cubic metres of water saved per year.

The consumption of fresh water for industrial purposes must decrease in the upcoming years; GWE dedicates its effort to test different proprietary technologies to help its customers to close the water loop at their factories.

Every solution GWE develops demonstrates that sustainable development and business profitability are not mutually exclusive concepts. The innovations GWE focuses on support this objective by providing highly effective technologies to tackle the environmental issues companies face in the 21st century.

To get in touch, please fill out the enquiry form.

Products and Services

Biogas Valorisation and Burner Conversion

Biogas generated during anaerobic treatment of wastewater and organic solid waste brings an enormous green energy potential for the food and beverage production facilities.

A Full Scope of Operation & Maintenance Services

Turnkey environmental solutions and O&M Services.

RAPTOR® A Complete Waste-to-Energy Solution

RAPTOR® stands for RAPid Transformation of Organic Residues. The system is a total solution, from the logistics for the organic waste intake and handling and ending with the production of green energy.

Water Reclamation Plants for High-Quality Process and Cleaning Water

GWE water reuse plants are custom-engineered installations that put in place multi-barrier systems to treat effluent from wastewater treatment plants.

ANUBIX – T EGSB Anaerobic Reactor

Our ANUBIX™ range of anaerobic upflow reactors reflects our clients’ needs and how far we have come since 1991 to meet them.

FLOTAMET Anaerobic Digestion System for High FOG and TSS Waste Streams

Heavily polluted with fat, oil, grease and solids, post-production wastewaters can be very troublesome to treat.

Video

White Papers

Related Projects

Press Release

One of Russia's biggest starch manufacturers, Gulkevichsky Starch Factory (KZG) doubles its corn processing capabilities and mitigates the environmental impact by installing a new wastewater treatment plant from Global Water & Energy (GWE).

Read moreGuatemala-based brewery Cervecería Centro Americana (CCA) is enhancing its environmental performance by using Global Water & Energy (GWE) technologies to convert the organic matter of the wastewater into biogas while achieving effluent quality improvements of 97% in organic matter removal.

Read moreCarnes de Coclé, a Panamanian international exporter of meat products, is setting high environmental standards for the meat processing industry with a new Global Water & Energy (GWE) wastewater treatment plant engineered to achieve 98% organic matter* removal from the post-production wastewater.

Read moreBeavertown Brewery has recently joined the list of forward-thinking companies by adopting the best practices in reducing the environmental footprint of its production facility in Enfield, UK.

Read moreRegional Offices

Koningin Astridlaan 29

8200 Bruges

Belgium

1314 Commerce Ave Ext

Richville Corporate Center

Ayala Alabang, Muntinlupa

1770 Metro Manila

Philippines

#1603, 16th Floor, 53 Sivatel Tower

Witthayu Road

Lumpini, Pathumwan

10330 Bangkok

Thailand

930 South Bell Boulevard Suite 204

Cedar Park

TX 78613

United States of America

Six Battery Road, #42

Singapore 049909