METTLER TOLEDO has announced the release of the latest version of its CIVCore software, featuring the Dot Print tool, the winner of the WestPack Innovation Award 2017.

While the Dot Print tool gives manufacturers a reliable method for inspection of inkjet and other dot matrix style prints, there are also several other features that help to improve CIVCore’s flexibility and user-friendliness.

One important change for the new version is the support of different hardware configurations, allowing METTLER TOLEDO to offer an increased range of configuration options. This also makes it easier to upgrade older vision systems.

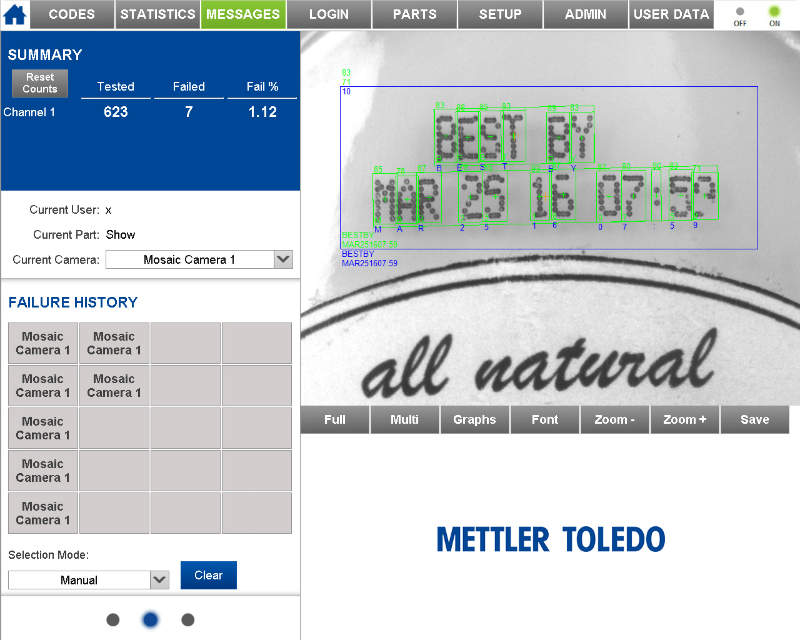

Another improvement is the merging of the client and server applications for CIVCore into a single application. This has resulted in significant speed increases on all systems, but particularly in systems using METTLER TOLEDO Mosaic Inspection technology. An added benefit of this unification is simpler logging and error handling, which makes diagnosing problems much easier.

However, the centrepiece of the new software is the Dot Print tool, which accurately reads characters that have been printed using discrete dots (aka dot matrix printing). This tool is specifically meant to help manufacturers verify the accuracy and quality of inkjet printing systems used to apply variable information such as the expiration date on food.

The Dot Print tool’s ability to compensate for distortion due to movement on the production line or uneven surfaces makes it far more accurate than past attempts, and multi-line reading capabilities allow CIVCore to quickly process images and keep up with rapid production speeds.

METTLER TOLEDO CI-Vision is a wholly owned subsidiary of Mettler-Toledo, a global supplier of precision instruments with sales and service locations in 37 countries. The METTLER TOLEDO Product Inspection Group consists of CI-Vision, Hi-Speed and Safeline. It is the world’s leading supplier of in-line checkweighers, metal detectors, machine vision systems and X-ray inspection systems. Industries including food, beverage, pharmaceutical, nutraceutical, personal care, plastics and chemicals use the company’s solutions to continuously improve the quality of their products and improve the efficiency of their manufacturing and packaging processes.