Selo Processing and Packaging Systems for the Food Industry

Selo has 65 years’ experience of supplying high-quality processing and packaging systems to the food industry. During this period of time we have gained vast experience that enables us to support some of the world’s leading food manufacturers in soup, baby food, mayonnaise, dressing, aseptic fruit, fruit preserves and cooked sauces.

Food processing equipment and installations

We supply turnkey projects for preparing, mixing, cooking, cooling and packaging of various types of products, including the following.

Soup processing lines

We supply fully automatic processing / production lines for ready, pasteurised and fresh soup such as tomato, onion, mushroom, etc.

Baby food processing lines

We also supply fully automatic processing / production lines for cooked, pasteurised, UHT and chilled product such as baby food, starting from four months to weaning.

Mayonnaise and dressing processing lines

We provide fully automatic processing / production lines for cooked, pasteurised and chilled mayonnaise, ketchup, curry sauce and dressing.

Aseptic fruit processing lines

We also offer fully automatic processing / production lines for cooked, pasteurised and chilled products for dessert toppings.

Fruit preserves processing lines

We have fully automatic processing / production lines for cooked, pasteurised and chilled products such as jam, confiture, marmalade and jelly.

Cooked sauces processing lines

We also supply fully automatic processing / production lines for cooked, pasteurised and chilled products like pizza sauce, pasta sauce, spaghetti sauce and meat / vegetable sauce (with or with pieces).

High-capacity food processing lines

Features and benefits of our food processing lines include:

- High capacity

- Good colour and taste

- High vegetable, fruit, pasta and meat integrity

- Both frozen and fresh vegetables can be used

- Hygienic design

- Quick change-over and low waste at recipe change

- Both hot and cold fill possible

- Minimum damage to the product

- Both frozen and fresh fruit are possible

- Easy cleaning

Preparation, cooking and cooling systems

In addition to our food processing lines, we offer a range of preparation, cooking and cooling systems, including:

- Batch systems from 300kg to 3,000kg

- Batch cooking and cooling systems from 300l to 2,000l

- Continuous systems from 1t/hr to 10t/hr

- Starch preparation systems

- Pre-mixing system

- High-pressure cooking systems

- Aseptic processing

- Vacuum cooking and cooling systems

- CIP and SIP systems

Custom process and packaging systems for the food industry

Selo process and packaging systems are used throughout the world and we are familiar with local cuisines and operating conditions. Our in-house experts work closely with our customers to ensure that we supply a system that efficiently produces a product to match customers’ expectations. From conception through to installation Selo uses its knowledge and experience to supply a total solution that matches its customers’ requirements.

Selo has an in-house pilot plant that provides customers with the opportunity to simulate processes so that it can be clearly demonstrated how their products will be produced. This system can also be used for testing so that recipes can be altered or improved.

Due to the scope of equipment we supply, we know that it is imperative that our customers receive a reliable after-sales service. Our service team ensures that customers have full support 24hr a day and seven days a week.

Selo is represented throughout the world and has sales offices in Germany, Belgium, Denmark and the UK. We also have agents in the US, Russia, Ukraine and France.

Products and Services

Video

White Papers

Related Projects

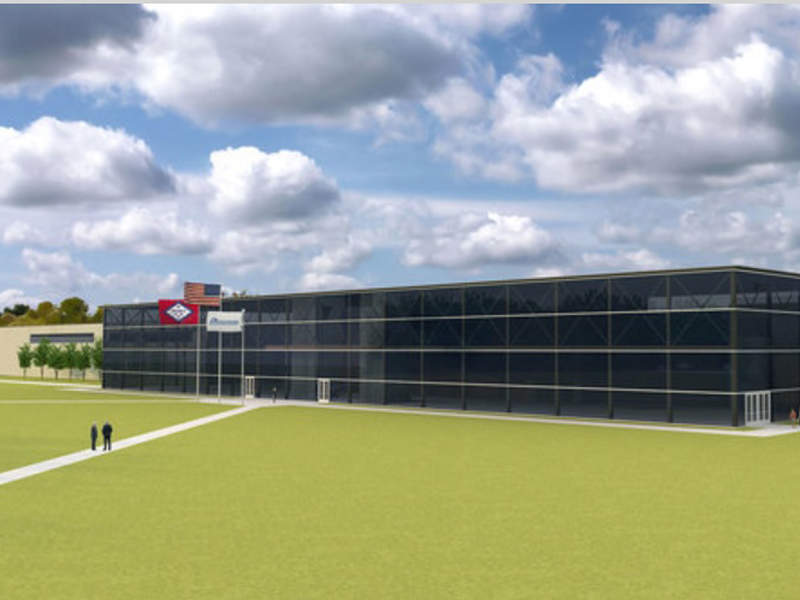

Simmons Prepared Foods Chicken Processing Facility, Arkansas, US

Tyson Foods’ Chicken Processing Facility, Tennessee, US

Univer’s Tomato Processing Plant

Bettcher Innovation Centre (BIC), Ohio, US

Press Release

Regional Offices

Eektestraat 1

7575 BV Oldenzaal

Other

Netherlands