Graco introduces the Husky™ 3300, a 3in (76.2 mm) air-operated double diaphragm pump family. This new pump family features a modular, stall-resistant air valve design, which can achieve flow rates up to 1,135l a minute (300gpm). The pumps also use a pilot valve for faster change over, maximising efficiency and reducing pulsation.

Graco introduces the Husky™ 3300, a 3in (76.2 mm) air-operated double diaphragm pump family. This new pump family features a modular, stall-resistant air valve design, which can achieve flow rates up to 1,135l a minute (300gpm). The pumps also use a pilot valve for faster change over, maximising efficiency and reducing pulsation.

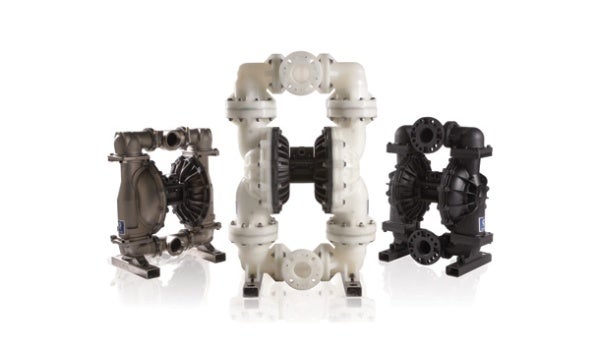

The Husky 3300 pumps are available in three materials of construction, including aluminium, polypropylene and stainless steel. In addition, there are numerous ball, seat and diaphragm material configurations to handle a wide range of abrasive and corrosive applications.

The pumps also have a four bolt joint design, which provides even sealing pressure for leak-free operation and a three-piece manifold for increased installation flexibility. The new polypropylene version has a fluid section containing an over-moulded frame that decreases joint relaxation and increases strength to virtually eliminate fluid leakage.

Graco’s DataTrak™, an optional integrated local monitoring system, can be added to any Husky 3300 pump to prevent pump runaway due to a damaged line or empty container. Pulse output is also available which allows cycle count capability to schedule proactive maintenance on the pump.

Graco’s pumps provide process solutions for numerous abrasive and corrosive applications and are built for years of reliable service.