BAADER Machinery and Solutions for the Fish, Poultry and Meat Processing Industry

The BAADER Group is a world renowned manufacturer and supplier of advanced high-quality food processing machinery and solutions for the fish, poultry, meat, fruit and vegetable processing industry.

BAADER also carries out project engineering for processing facilities on board or on shore. Service centres and subsidiaries at more than 80 locations throughout the world, highly precise spare-parts, as well as daily spare-parts dispatch guarantee the customer maximum benefit and high productivity.

Fish processing – stunning, bleeding, chilling, gutting, heading, filleting, skinning, trimming, pinboning

The traditional support of the group of companies is the extensive programme of fish processing machines and solutions. BAADER can offer machines for stunning, bleeding, chilling, gutting, heading, nobbing, skinning, filleting, trimming, pinboning, weighing, grading and bone separating of almost all species of edible fish, such as salmon, trout, sea trout, whitefish, herring, mackerel, Alaska pollack, cod, saithe, haddock, flatfish, tilapia, pangasius, catfish, and many others.

BAADER also carries out project engineering for complete processing lines for processing facilities on board or on shore.

We are able to provide a full range of technically advanced fish processing machinery to our customers. We are dedicated to developing state-of-the-art equipment for more efficient, safer and financially viable fish processing.

Weighing, grading and production management software, yield control

BAADER is also aware that food processors are always searching for improved ways to monitor and control their production. BAADER is taking care of this challenge and offers a production management software, B’Logic, to monitor and optimise overall production performance. Baader supplies the customer with all real-time key results for each stage with full traceability, and gives the manager the possibility to make necessary real-time adjustments to optimise yield, quality and throughput.

Together with our BAADER Logistix division – responsible for weighing, grading and business software solutions – BAADER is a full system supplier.

Poultry processing machinery

LINCO Food Systems is part of the BAADER Group. Together we are able to provide a full range of technically advanced poultry processing machinery and solutions to our customers, including machines for slaughtering, evisceration, cut-up, chilling, deboning, X-ray bone detection, etc.

We are able to provide a full range of technically advanced poultry processing machinery to our customers. We are dedicated to developing state-of-the-art equipment for more efficient, safer and financially viable poultry processing.

Product refinement, desinewing, mincing, depackaging

As far as the meat processing industry is concerned, BAADER is a market leader with its belt separators since they are perfectly designed and suitable for most applications, such as desinewing, mincing, pulp production, depackaging, etc. The BAADER method is a technologically unique way of precise meat cut-up and the basis for industrial sausage production. In practice, the process is logically called ‘baadering’.

Worldwide service for meat and fish processing equipment

Our enterprise has met the challenge of the market to reach higher quality standards for our services and a good cooperation with our customers. It is an integral part of our quality policy. We want to belong to the most efficient and most customer-oriented enterprises in our area of expertise.

Production

Since its foundation, the BAADER company has been attaching much importance to state-of-the-art production technology in order to ensure the precise manufacture of many thousands of individual parts. A comprehensive quality assurance system guarantees a defined quality.

BAADER Germany is certified according DIN EN ISO 9001:2008.

Research and development

Research and development have a particular rank in the company. Experienced graduated engineers, electronics engineers, technicians and mechanists are working in laboratories, design and research departments to find innovative solutions for the manifold tasks.

Only those companies pursuing research and development can offer to their customers innovative solutions at the highest level. Today BAADER is a self-reliant, team oriented and group independent company whose corporate policy is to achieve the highest efficiency and cost effectiveness with dependable, productive and reliable products and solutions.

Products and Services

BAADER 221: Automatic Pelagic Processing Line

Customer benefits: High throughput

BAADER 581: High-Speed Filleting Machine for Salmon

Customer benefits: high speed: up to 25 fish/min

BAADER 604: Gentle Product Refinement

BAADERING™: Worldwide proven method for separating soft and solid components

Grading / Weighing / Sizing

Whole fish grader: packing into tubs and/or boxes for small to medium-sized products

BAADER 144: High-Speed Gutting Machine for Salmon

The BAADER 144 salmon gutting machine presents many benefits to customers, including high speeds of up to 25 fish per minute, a wide working range between 2kg and 5kg, and less after-cleaning due to a very stable and perfect cleaning result.

Video

Related Projects

D’Orsogna Manufacturing Facility, Melbourne, Australia

Beyond Meat’s Manhattan Beach Project Innovation Centre, California, US

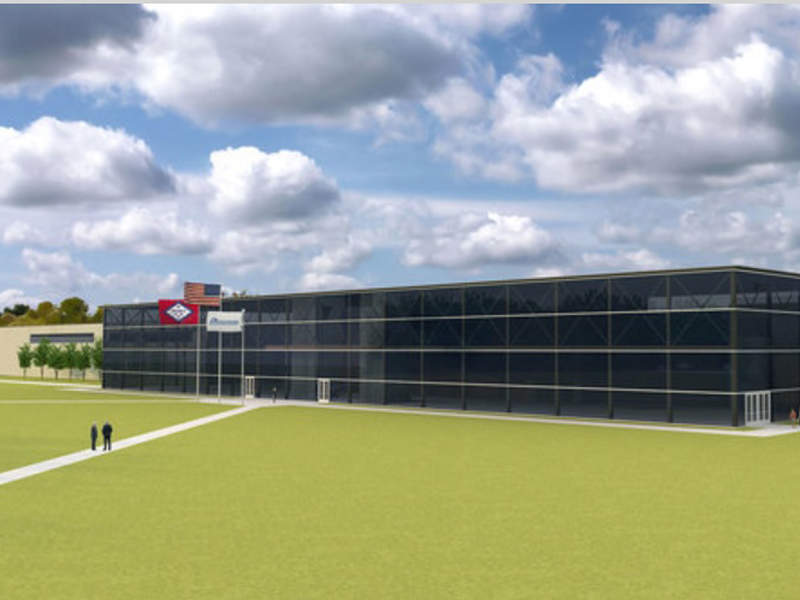

Simmons Prepared Foods Chicken Processing Facility, Arkansas, US

Tyson Foods’ Chicken Processing Facility, Tennessee, US

Prestage Foods’ Pork Processing Plant, Mason City, Iowa, US

Pilgrim’s Pride’s Poultry Processing Complex Expansion, Kentucky, US

Euro-Baltic Fish Processing Centre Expansion

Press Release

Optimised for skinning fresh or smoked salmon, the specially designed Easy-Grip BAADER 240 leaves no skin on the fish's tail and guarantees high-yield.

Read moreBAADER's new machine, BAADER 581, produces high-quality fillets with a high-yield. The machine is designed with respect to hygiene, food safety, maintenance, performance, fillet quality, production control, and speed.

Read moreDemonstrated at BAADER's salmon@baader event, the BAADER 144 Salmon Gutting Machine and Speed Feed System has shown improved speed, cleaning performance, working range, and hygiene, as well as an automatic camera detection of the cleaning result.

Read moreBaadar has explained the benefits its stunning and bleeding methods at the salmon@baader event.

Read moreLerøy Midt signed the contract with BAADER to be part of the new Salmon Processing factory in Jøsnøya on Hitra.

Read moreBAADER has launched a new event in its new state-of-the-art technology centre in Leubeck.

Read moreBAADER's new skinning machine for salmon is designed for twin or single lane skinning.

Read moreThe new BAADER 144 salmon gutting machine together with the new Speed Feed system is a game changer in the salmon industry.

Read moreJBT Corporation and Nordischer Maschinenbau Rud Baader GmbH (The BAADER Group) have announced a co-operation agreement.

Read moreBakkafrost is building a new state-of-the-art salmon factory at Glyvrar to centralise their processing capacity.

Read moreThe BAADER 136 produces a trout which seems to be complete - with head and tail - but it is indeed boneless and ready for preparation.

Read moreThe BAADER technology for clean separation of fish meat from bones, fins and skin, which was developed in Luebeck, Germany, keeps setting new benchmarks when it comes to performance and product quality.

Read moreBAADER is proud to introduce the new BAADER 588 filleting machine for fresh and defrosted whitefish.

Read moreBAADER offers the most humane and efficient method for stunning and bleeding of salmon/trout and many other fish species, utilising percussive stunning.

Read moreThe BAADER-Group will be demonstrating its competence in pinboning at this year's Seafood Expo Global/Seafood Processing Global event in Brussels.

Read moreSinkabergHansen has invested 25 million Norwegian kroner in a new processing factory and new BAADER equipment. "With innovation we doubled our capacity for fresh fillets," says Svein Gustav Sinkaberg.

Read moreNova Sea is a well known company in the salmon industry and is known worldwide for its excellent products. It has always been a pleasure for BAADER to work and to continue working with Nova Sea.

Read morePetra Baader, Honorary Consul of Norway, CEO and shareholder of the Baader Group, and Bruce Goodrick, founder and owner of Seafood Innovations and Seafood Innovations International Group, have closed a transaction under which Baader takes over certain assets and the business activities of the Australian producer.

Read moreThe BAADER technology of clean separation of fish meat from bones, fins and skin that was developed in Luebeck, Germany, keeps setting new benchmarks when it comes to performance and product quality.

Read moreThe BAADER Group has purchased 100% shares of the company Trio Food Processing Machinery in Norway together with the daughter company Trio FTC Sweden.

Read moreTogether with TRIO, the BAADER group has developed a solution for removing pin bones in atlantic salmon fillets post-rigor shortly after slaughtering.

Read moreThe BAADER Group, a worldwide operating company with origin and headquarters in Germany, sees great opportunities in the Vietnamese seafood market. Therefore this year the BAADER Group took part in the Vietfish trade show for the first time. The Vice-Minister for Fishery, Luong Le Phuon

Read moreProviding the best solutions to produce safe food, safely processed worldwide Food contamination and worker safety issues in the fish processing plants are of ever increasing concern facing the industry. BAADER has addressed this issue by standing for a commitment to provide th

Read moreFrom Gutted Fish to Trimmed Fillet with Addition of BAADER 1900 BAADER offers complete processing solutions to the industry – from heading, filleting, trimming, final inspection to sizing and grading, thanks to integrating the BAADER 1900 into the line. This system is the key

Read moreWe are proud to introduce the new BAADER 59 whitefish skinner, debuting at the upcoming Seafood Processing Europe trade show in Brussels April 22-24. The machine was specially designed for cod, saithe and haddock, and is gentle enough to handle the soft meat of many other whitefish. The

Read moreRegional Offices

Nordischer Maschinenbau

Rud.Baader GmbH+Co.KG, Geniner Str. 249

D-23560 Lübeck

Germany