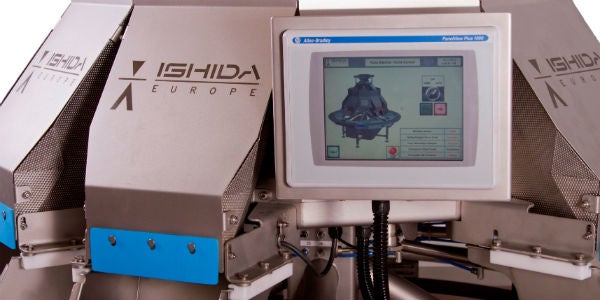

A close-up of the Roto-Batcher with hoppers and a touch-screen.

Ishida Europe has introduced a second model into its weigh batcher range. The new Roto-Batcher combines the accurate weighing of fresh meat and poultry with manual manipulation to optimise their arrangement and presentation in trays, while its circular rotary batching table, positioned directly below the weigher, also maximises the return on floor space.

The Roto-Batcher has been developed for sticky meat and poultry products which cannot be easily moved by feeder vibration, or for when manual product feeding is not economically viable. Using eight operators, the system can deliver speeds of 55 trays a minute with an average giveaway of only 1%.

Product is weighed automatically on Ishida’s proven Screw Feeder weigher and each accurately-weighed portion is then despatched to one of the packing stations on the batching table, where an operator transfers it to a tray, styles it and places the tray on an ‘out’ belt for sealing, labelling and quality control. The station automatically informs the system once the filled and styled tray has left, triggering the sending of another weighed item to be packed.

The Screw Feeder weigher has been specifically designed for sticky, difficult-to-handle fresh products and features rotating metal spirals that provide a powerful, controlled and fully automatic product feed to the pool hoppers. Using the Ishida R Series’ unique calculation processing software, the weigher can easily double packing speeds for the stickiest of products while minimising giveaway.

The Roto-Batcher incorporates a user-friendly control panel, which allows the performance of each operator and each shift to be monitored. An easy-clean design meets the stringent hygiene demands of the meat and poultry industry.

Ishida says that as well as fast speeds and minimal product giveaway, the new system can reduce labour by up to 60% compared with an entirely manual operation.