BigBag’s have many advantages. No cleaning or checking of cleaning is required; there is no empty container transport and no maintenance on inlet and discharge units. However, one sticking point has always been that it is very difficult to fill and empty BigBag’s without causing the release of a significant amount of dust. The docking and undocking procedure was complicated and could scarcely be performed single-handedly. SmartDock provides a solution to this issue.

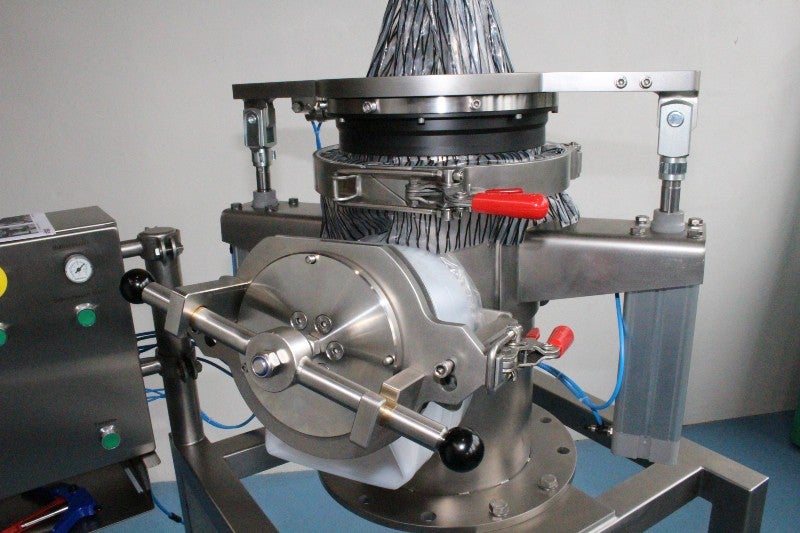

About seven years ago, Rubitec developed the SmartDock system for BigBag’s and applied for a patent. Thanks to its simple and fast handling, the docking system has impressed a large number of users in a very short time. It actually requires just one person to operate it. It does not require access from all sides: access from one side will suffice. A BigBag can be docked and undocked in five minutes. The height of the docking head can be reduced to the extent that – depending on the necessary fixtures (nozzles) – favourable ergonomics is feasible for most applications.

A few more advantages

With SmartDock, no additional sheeting is required for the connection between the BigBag and the docking head. This ensures that the solids flow only through the user-defined sheet quality of the BigBag inner bag. To protect the sheet nozzle of the inner bag from excessive mechanical stress or against pressure surges, the outer bag nozzle can also be fixed. The inner bag is thus supported along its entire length.

In contrast to conventional systems with two O-ring grooves, the SmartDock system has a triple seal between the process chamber and the surrounding area. Rubitec AG developed a seal of the type used for the process chamber many years ago, in order to be able to seal multi-folded sheets against fluid pressure. It is with this proven system that the SmartDock also managed to achieve the highest levels of impermeability. Big bags with aluminium-coated inner sheeting pose a particular challenge.

These sheets are used when the plastic alone is not diffusion-tight enough vis-à-vis the solvents contained in the solid, which would therefore diffuse through the plastic sheet. These laminated aluminium sheets are not nearly as smooth as a pure plastic sheet and are also thicker than the latter; they are therefore more difficult to handle and to seal. The SmartDock has also been effective when used with laminated aluminium sheets. There have been no disadvantages detected when compared to pure plastic sheeting.

Another important advantage is that the SmartDock uses no “loss parts” such as O-rings, auxiliary rings, or other parts: loose parts which are needed upon each docking for some systems. This not only reduces the cost of consumables, but – more importantly – the loose parts cannot enter the product during undocking, which can result in costly searches.

Cleaning is also easy to carry out without the containment process being interrupted. Because during BigBag filling there is often a sheet hood at the lowest point, where the cleaning liquid then collects, the hood must be removed without interrupting the containment process. The SmartDock standard accessories include a very simple solution for this and also a separate push-filter system with H13 exhaust filters. The filter cartridge can be cleaned during operation and can also be replaced without interrupting the containment process.