HECHT Food Handling, Containment and Production Machines

HECHT provides secure material bulk handling solutions for the transfer of raw materials in the food industry.

The company’s flexible systems meet the high-containment and hygienic conditions required for food manufacturing processes while improving operator safety. Applications include dosing, sampling, pneumatic and mechanic conveying, as well as single-use technology production.

HECHT offers comprehensive plant engineering that is complemented by on-site support.

Process equipment for continuous manufacturing of food products

HECHT’s production equipment is designed to increase operator efficiency and safety in continuous manufacturing (CMT). The systems are designed using the firm’s extensive experience in raw material handling.

The company’s experts keep up-to-date with current regulatory requirements in the food sector and ensure that the process equipment meets new guidelines. The machines are made from materials that adhere to guidelines from regulatory agencies such as the US Food and Drug Administration (FDA).

HECHT’s cleaning and automation concepts ensure the traceability and purity of each food batch and its machines are suitable for clean-in-place (CIP), wash-in-place (WIP) and dry-in-place (DIP) methods.

Flexible intermediate bulk container filling and discharging

HECHT develops modular stations for the filling and discharging of flexible intermediate bulk containers (FIBC) such as super sacks, bags, drums, containers and cartons.

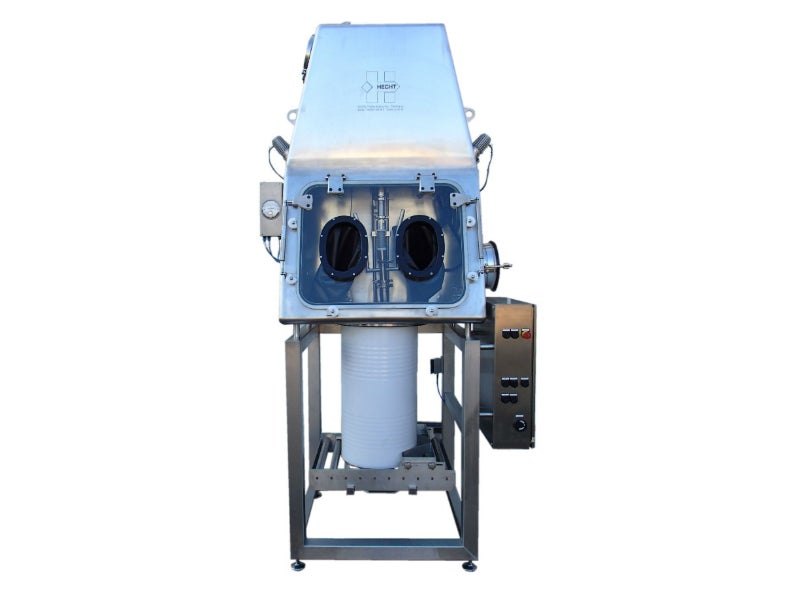

The company’s containment solutions restrict production within liners, gloveboxes and butterfly valves to prevent dust and powders from accumulating in the working environment. The systems are designed to the Standardised Measurement of Particulate Airborne Concentration (SMEPAC).

HECHT’s simple-to-use manufacturing machines are designed to deliver overall equipment effectiveness and cost-effective, state-of-the-art systems.

Engineering services for food manufacturing plants

HECHT’s engineers provide consultation services for customised projects ranging from initial plan recommendations to final assembly and commissioning.

The company can offer services at any stage of a project, either for a single phase or a turnkey solution.

HECHT helps ensure plant availability and continuous quality control. The company’s high-quality engineering services meet the high-performance requirements of food production facilities.

About HECHT

Founded in 1978, HECHT has more than 80 employees. It provides services to more than 1,000 customers across the pharmaceutical, food and chemical industries.

Its customised solutions ensure in-house transfer of raw bulk materials and the development of more than 10,000 projects worldwide.

The company offers special purpose machinery for high-containment applications, guaranteeing a high level of both operator and product protection. Whether it is filling, discharging, dosing or vessel weighing, HECHT finds a suitable solution that can be combined and adapted to meet specific requirements.

Products and Services

Drum Discharger CFE-K (Drum Dump Station)

The HECHT Containment Drum Discharger CFE-K with tipper device is used for low-contamination discharging of drums with inner liner up to OEB5. By means of the tipper, the drum can be easily mounted to the station.

Vacuum Conveyor PCC

With the ProClean Conveyor (PCC), HECHT developed an extremely flexible and reliable conveying system.

FIBC Discharging

Connection Systems are the core component for a safe FIBC discharging process. Depending on the product, operating location and containment requirement, HECHT has developed different systems

Bin Filling Stations

Bin Filling Stations normally consist of various components. The heart of every system is the filling head. Depending on the application, a filling head for individual filling of single sacks or liners can be integrated or a filling head with continuous liner can be connected.

Drum Discharger CFE-L (with Suction Lance)

HECHT's Containment Drum Discharger with lance type CFE-L is used for contamination-free discharging of drums with an inner liner up to OEB 5.

White Papers

HECHT Sampling Solutions for Food Processing Applications

It is a key topic within any kind of industry and branch to maintain constant and steady product quality.

Choosing the Right Automated Blending System

The right blending and automated systems depend on the requested function and the raw materials HECHT's customers intend to process.

Compact Sack Discharge Stations

Sack Discharge Stations are easy to operate and require hardly any training. Their compact design is easy-to-clean and it allows for fast sieve replacement without the need for tools.

Pneumatic Conveying Systems for Powdered and Granulated Food Products

The HECHT ProClean Conveyor (PCC) is intended for the safe and gentle conveying of powders and granules in the pharmaceutical, chemical and food industry. Its special filter head improves your efficiency and other various possibilities for a more flexible configuration of your system.

Discharging Flexible Intermediate Bulk Containers (FIBC)

Flexible intermediate bulk container (FIBC) discharge stations by HECHT are used in the chemical, pharmaceutical and food industries.

Containment Drum Discharge Stations

The HECHT containment drum discharge station with lance type CFE-L is used for contamination-free discharging of drums with an inner liner up to OEB 5.

Powder Handling Systems for Neutraceuticals

HECHT provided powder handling systems for conveying, dosing, feeding and discharging to a large and well-known supplier of neutraceutical products.

Related Projects

Press Release

HECHT patented Liner-Connection-System LAS-EC 'Easy Connect' enables a defined, safe discharging of FIBCs with a logical operating procedure in just a few steps up to a containment level of OEB 4 (OEL 1-10 μg/m³).

Read moreThe new flexible dosing system (FDS) from HECHT is a hygienic, product-gentle dosing system used for metering in the product stream.

Read moreHECHT's new sleigh sampler is an optional pneumatically or manually driven inline sampling system.

Read moreHECHT has announced the release of a new sample carousel. First released earlier this year, the unit is designed for frequent in-process control and automatic transfer to different vessels.

Read moreEarlier this year, HECHT released a new and developed drum emptying system with a suction lance. The machine is used for simple ergonomic discharging drums with and without inner liners.

Read moreHECHT is preparing for the next POWTECH show, taking place in Nuremberg, Germany.

Read moreRegional Offices

Schirmbeckstraße 17

85276 Pfaffenhofen an der Ilm

Germany

1020 Monterey Blvd. #2

Hermosa Beach, CA 90254

7 Murphy Drive Maynard Green

Bagworth

LE67 1HR Leicestershire

15 bis rue de Tourville

78100 Saint Germain en Laye

C.I. Santiga - C/.Flassaders, 14-16

08130 Sta. Perpètua de Mogoda

Kutomotie 16

00380 Helsinki