Honeywell Industrial Combustion Combustion Equipment for the Food Industry

Honeywell Industrial Combustion is part of Environmental and Combustion Controls, which is a division of Honeywell Automation and control Solutions. Honeywell Industrial Combustion is a market leader in delivering fully engineered burner systems, sub assembly pipe trains and control panels, along with safety components and controls. Our expertise and knowledge delivers high-value solutions focused on improving energy efficiency across a wide range of vertical markets.

Burners for food processing

Honeywell Industrial Combustion has a broad variety of burner types to serve the industrial process industry. From glass ovens to textile dryers, from printing machines to waste incinerators, in heavy petrochemical industry or small make up air units, Honeywell Industrial Combustion can always supply the correct burner for the specific need of the application.

Complete combustion systems

The burner is obviously the heart of a combustion system, but it won’t function properly without the help of a tailor-made gas pipe train, control panel and adapted combustion chamber. Honeywell Industrial Combustion designs and builds these complete systems. With the aid of a skilled team of combustion engineers, backed up with decades of experience, Honeywell Industrial Combustion is able to produce the most reliable and efficient combustion systems offered to the market today.

Burner combustion chambers

The performance of a burner does not depend entirely on the burner itself, but, to a large extent, on the way the burner flame can develop. Since this requires a profound knowledge of combustion physics, Honeywell Industrial Combustion can design and build a combustion chamber which will hold the burner and allow the flame to develop as necessary. This way, customers can be sure that the burner system will perform to its maximum capability.

Gas pipe trains

A gas pipe train contains all the components required for a safe and precise fuel and air supply to the burner. The standards to which these pipe trains need to comply are very specific, and depend on the application and the destination country of the burner system. Honeywell Industrial Company, as a worldwide company, can supply gas pipe trains according to all common global standards.

Control panels for combustion systems

To operate the burner and pipe trains, a burner management system is required. Depending on the process control system, Honeywell Industrial Combustion can design and build a customised control panel. These panels are made to a very high standard and are all tested in our production plant, whilst connected to the gas pipe train and burner. This ensures a smooth and trouble-free start up of the system.

Oil and gas shut-off valves

MAXON valves are available with a broad range of trims to safely shut off almost every gas or liquid imaginable, from general purpose to corrosive gases or oxygen. Powerful closing springs provide a reliable closing force to ensure the safe shut off of fuel. The unique guillotine design ensures extremely low pressure drops for a given line size, and adds a self-cleaning stroke to valve operation.

MAXON gas valves are the only fuel shut-off valves with metal-to-metal seats that ‘wear in’ and not out. They are available with electrical or pneumatic actuators.

Flame monitoring systems

A range of flame monitoring systems is available for use in the petro-chemical, pulp and paper and power generation industries, as well as in applications where the detection, monitoring and control of furnaces and boilers are required.

Industrial burner controls

Honeywell Industrial Combustion offers various models of microprocessor-based industrial burner controls for automatically fired gas, oil or combination-fuel single-or-multi-burner applications. This includes all types of unlimited-capacity burners, and intermittent or continuous operation, depending on the model.

Energy-efficient burners for the food industry

Honeywell Industrial Combustion is well established in industrial food applications such as bakeries and food dryers.

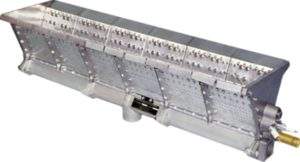

Infrared burners have been used in bakery lines to significantly reduce fuel consumption. Classic hot air bakery lines are commonly equipped with Honeywell Industrial Combustion’s classic MAXON OVENPAK® burner. This extremely reliable and flexible burner is a classic in the industry, on coffee roasters, rice dryers, etc.

The MAXON NP-LE® line burner is commonly used in grain dryers. This burner is mounted directly in the process air stream and uses the oxygen in the process air for combustion. Therefore there is no need for external combustion air fans, making this the most energy-efficient way of heating the product to be dried.

Ultra low NOx burners

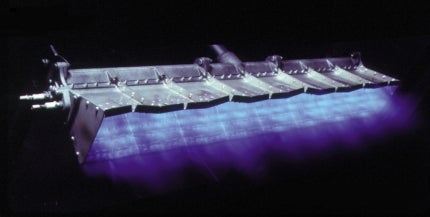

Honeywell Industrial Combustion owns the patent to commercially use Shear Layer Stabilisation (SLS) combustion technology. This contra-intuitive method of air/gas mixing inside the burner, developed by the Department Of Energy (DOE) in the US, results in near zero NOx levels.

The MAXON M-PAKT® and OPTIMA® burners use this SLS technology, and have been successfully integrated in powder milk spray dryers. The combination of direct heating and low NOx results in a high-quality end product and low fuel consumption.

Products and Services

Video

White Papers

Related Projects

Press Release

Regional Offices

Luchthavenlaan 16

1800 Vilvoorde

Flemish Brabant

Belgium

Archimedesstraat 12

3316 AB Dordrecht

South Holland

Netherlands

Chantry House, High Street

Coleshill

Birmingham

West Midlands

United Kingdom

12, Chaussée Jules César

BP60339-Osny

95526 Cergy-Pontoise Cedex

France

Via Sarfatti 26/4

20136 Milano

Milan

Italy

Gottlieb-Daimler Straße 17

71394 Kernen

Germany

Çayıryolu Sokak No:7 Üçgen Plaza

Kat:7 34752 İçerenköy

Istanbul

Turkey