When it comes to baked goods, besides taste it is visual appeal that counts. Professional and hobby bakers achieve this by decorating their creations with sweet icing sugar and fondant. The right process technology is crucial to the perfect texture and colour of the sweet coatings, and Ploughshare® Mixers can be relied on for the best results.

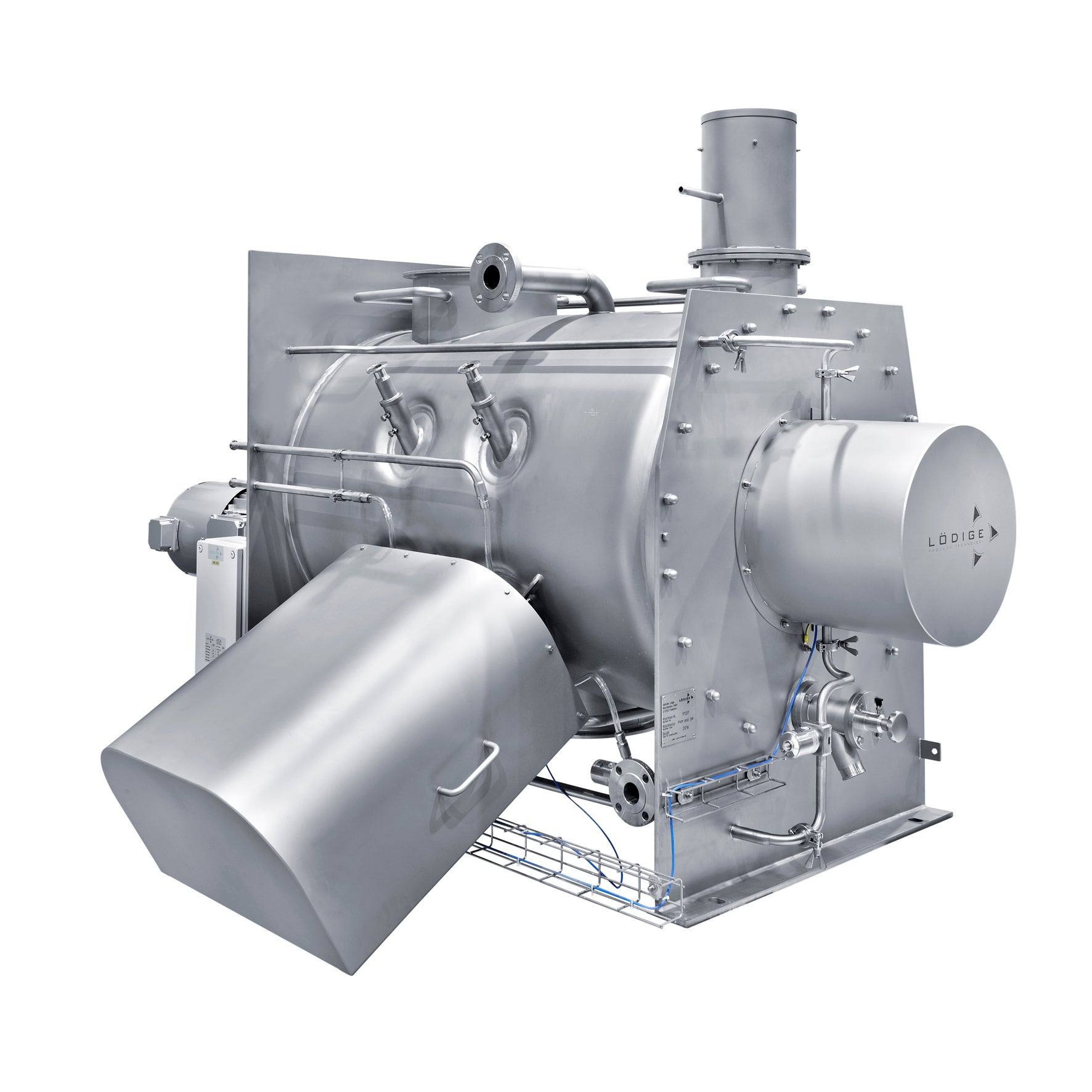

Ploughshare® Mixers operate based on the mechanically generated fluid bed, which Lödige introduced to industrial mixing technology. The operating principle can be briefly described as follows: Ploughshare® Shovels arranged on a shaft in a special system rotate as mixing elements in a horizontally aligned, cylindrical drum. These shovels create a three-dimensional movement of the components to be mixed. The resulting mechanically generated fluidised bed ensures fast, gentle and precise mixing. Separation of the particles in the fluidised bed facilitates the addition of liquids and particle coating. If needed, the mixing process can also be supported by high-speed rotating choppers. Thanks to their flexibility, Ploughshare® Mixers are very versatile in their range of applications.

Icing sugar: coating of powders

Whether fruit tart or cream cake, fruit loaf or strudel: “icing sugar” (also called “snow sugar”) is used for decorating and dusting, and adds the final touch to baked goods. Unlike conventional powdered sugar, the fine sugar crystals are coated with a layer of fat. This keeps them from melting, even at higher temperatures. Nor does the icing sugar dissolve, even when it comes into contact with greasy surfaces.

The physical and sensory product properties of icing sugar are rated as a standard for the trade when the following criteria are met:

- Appealing and natural white colour

- Full coverage adhesion

- Good flowability of the powder (no lumping or caking)

- Does not dissolve at an ambient or baked goods temperature of up to 45°C

- Forms a lasting sugar coating on baked goods with greasy surfaces

In the manufacture of icing sugar, a uniform premix is first created from the powdered raw ingredients (sucrose, dextrose, other sugar-based powders and aromas). A temperature control jacket is used to heat this premix to a temperature in the melting point range of the fat to be subsequently dosed in. Ideally, the double jacket is then heated to a temperature above the melting point of the fat, in order to prevent the product from sticking on the mixing drum walls. Subsequently, the fat is dosed directly into the rotating choppers, and the melted fat coats the powder. This also creates a granulate texture, which has a positive effect on the flowability of the powder. In the final step of the process, liquid nitrogen is injected into the mixer interior, cooling the product to approx. 20°C. This accelerated fat crystallisation prevents the product from lumping and caking.

For optimum shape and colour: homogenisation of fondant and sugar icing

Sugar icing and fondant, available in various colours, can turn baked goods into real showpieces. Both products can be economically manufactured in the Ploughshare® Mixer. While liquid sugar icing – comprised of powdered sugar and water (or fruit juices) – should harden after processing. Fondant has a soft or pasty, and thus mouldable, consistency. Which is why glucose syrup and other ingredients such as coloured food dyes, sugar substitutes or gelling agents are added in fondant manufacturing. The homogeneous sugar-glucose syrup mixture is heated in the mixer, and the introduction of mechanical energy converts it to a mouldable mass. The remaining recipe components are then added.

Fondant can be produced in mixers for both batch and continuous operation. The use of choppers is not necessary for this application. The rotational speed of the mixing tools can be infinitely adjusted to the respective recipe via a frequency converter.