Lödige Process Technology Mixers, Coaters, Granulators, Dryers and Reactor Systems

Lödige Process Technology offers high-quality customised machines, systems and services for process technology applications in the fields of mixing, granulating, coating, drying, reaction and related processes.

Lödige has a broadly diversified international customer base, consisting of companies from the food, pharmaceutical and cosmetics industries, as well as building materials and plastics, chemistry, metallurgy, cellulose, starch, minerals/ores and the environment.

More than 500 patents and over 35,000 machines and systems attest to Lödige’s experience with customer-oriented system solutions.

Solution and service provider for all processes

Lödige’s portfolio includes mixers, coaters, granulators, dryers, reactor systems, Ploughshare® Mixers, mixing technology, processing technology, mixing and fluidisation processes, mixed products and processing systems.

Our customers appreciate the high quality of the mixed products, together with the speed and efficiency of the machines. In addition, mixers can be individually tailored to the special requirements of the respective industries.

As a solution and service provider for all processes, Lödige delivers sophisticated operational sub-systems, and adapts them to the customer-specific processes and needs.

It goes without saying that as a one-stop solution provider, the company also offers turnkey installations. Lödige assumes all work stages from set-up to installation and commissioning of the turnkey solution.

In addition to focusing on core industries, proximity to the customer is for Lödige the key to sustainable corporate development. In addition to the individual application-specific design of each machine, this calls for reliable customer service by experienced engineers, ranging from the installation, subsequent upgrades and modernisation to the dismantling and disposal. This, of course, includes emergency support in the unlikely case of a breakdown.

Processing know-how for the food industry

Lödige systems offer the required mixing and process precision for ideal process design in a wide production range. Customers include well-known food industry brands.

The company’s systems and solution concepts are used worldwide, based on decades of practical experience in the design and construction of mixers and treatment systems for food producers. Lödige’s machine engineering solutions guarantee ‘hygienic design’ and implement extensive cleaning systems.

Lödige machines are built according to current international regulations for food-safe hygienic design, and are perfectly geared to your process. Our range of services is supplemented by broad after-sales support.

Process engineering solutions for food processing

Based on numerous process engineering options, Lödige systems can be designed and used for many products and production steps. For instance, in addition to the conventional mixing step, the additional process steps that are usually required by the food industry can be combined in one Lödige system.

This can make work-intensive pre-mixing, for example, unnecessary. Additionally, the Lödige test centre provides various solutions for experiments in process development and achieving a reliable scale-up to full production machines.

All systems listed below are available for production scale and in sizes suitable for laboratory work:

- Discontinuous mixing and granulation in a horizontal Lödige system

- Continuous mixing and granulation in a horizontal system

- Discontinuous mixing and granulation in a vertical Lödige system

- Mixing and processing in a continuous ring-layer system

- Drying and mixing in a vacuum shovel dryer

About Lödige Process Technology

Founded in 1938 in Paderborn, Germany, Lödige Process Technology is a family owned business in the third generation. With the invention of the Ploughshare® Mixer, Lödige created a mixing unit that can handle a wide range of different processing tasks.

Lödige currently operates with more than 500 employees worldwide, and supports its customers with a network of subsidiaries, technical offices and agencies.

The company has a subsidiary coordinating the entire North America business in Florence, Kentucky, US, and further subsidiaries in Spain and France. Joint ventures have been set up in India and China. Additional licensees are located in Brazil and Japan, and worldwide representations complete the worldwide Lödige network

Products and Services

Lödige Ploughshare® Mixer Type FKM for batch operation

Lödige Ploughshare® Mixer for batch operation: A well-established all-rounder

Lödige Ploughshare® Mixer Type KM for continuous operation

Lödige Ploughshare® Mixer for continuous operation: short retention times, constant reproducibility, the highest degree of homogeneity of the final product and versatile application

Lödige Coater Type LC light series (Focus on Nutraceuticals)

Lödige Coater Type LC light series for cost-efficient coating

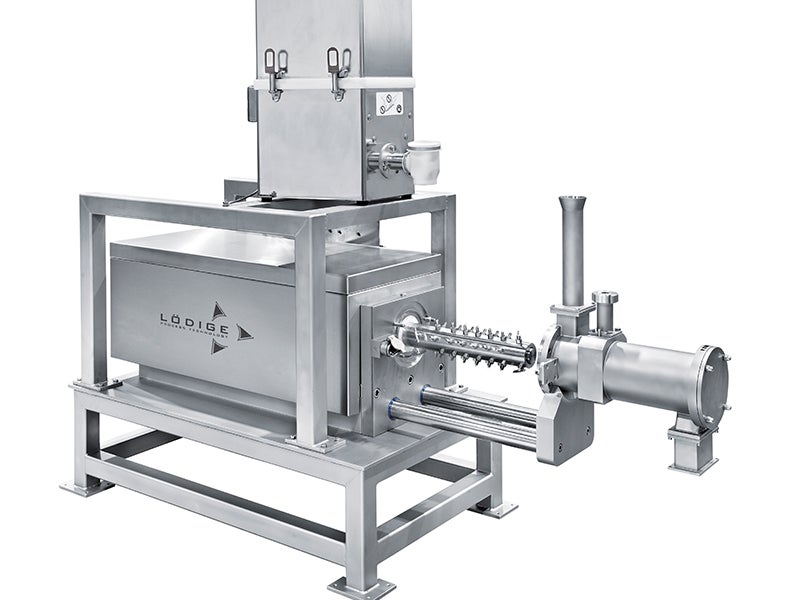

Lödige Mixing Granulator

Lödige Mixing granulator Type MGT

Lödige CoriMix® ringlayer mixer for continuous operation

Lödige CoriMix® ringlayer mixer for continuous operation: intensive mixing

White Papers

Related Projects

Press Release

Moisture-sensitive powder batter mixes such as those used to make crisps and other savoury snacks require a high degree of homogeneity combined with precisely controlled and extremely stable moisture levels.

Read moreLödige Process Technology has developed a granulator especially for compacting bulk goods such as tea or cocoa and coffee.

Read moreInstant soups and bouillon cubes are convenient and fast snacks, but the production demands complex process technology requirements.

Read moreNutraceuticals like vitamin preparations, mineral nutrients or dairy products, mostly contain more than 50 different products.

Read moreWith its L series, Lödige Process Technology offers laboratory mixers that combine the typical Lödige mixing quality with sophisticated equipment and ergonomic design.

Read moreIn addition to reliable process functionality, an efficient cleaning process of the horizontal mixing system like the Lödige Ploughshare® Mixer is becoming increasingly important.

Read moreA choice of process engineering alternatives is available for coating particles.

Read moreIn industrial production processes, chemical reactions are generally part of a multi-stage process chain comprising both the synthesis process itself and a number of processing steps before and after.

Read moreWhen it comes to baked goods, besides taste it is visual appeal that counts.

Read moreLödige Process Technology presents an entirely new model range: The LC light series.

Read moreWith the conche invented by Rudolphe Lindt in 1879 the chocolate required 72 hours to achieve its creamy, smooth consistency.

Read moreRegional Offices

Elsener Straße 7 – 9

33102 Paderborn

Germany