Oerlikon Balzers Advanced Surface Technology for Precision Components within Food Processing Applications

Oerlikon Balzers provides surface technologies designed to improve the performance and durability of precision food processing components.

With more than 70 years’ experience, the company’s BALINT and BALIQ brands represent a range of thin and hard coatings, its BALITHERM brand provides heat treatment services, and BALTONE comprises decorative coatings in a wide array of colours.

Plasma-assisted coating for food processing equipment

Oerlikon Balzers’ surface treatment methods help maintain the high performance and service life of food processing machinery by reducing the effects of wear and corrosion.

The company utilises a cost-effective, plasma-assisted coating process, which results in effective, reliable protection.

With extensive experience in thin-film physical vapour deposition (PVD) coatings, Oerlikon Balzers aims to consistently develop custom solutions that optimise plant performance. The company also offers a thorough support service through its professional project managers, offering assistance in early development and design phases.

Low-friction thin-film, PVD coatings

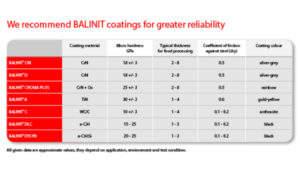

BALINT is a range of thin-film PVD coatings used to help protect non-lubricated processing machinery from corrosion.

The coatings help improve the reliability of equipment with applications such as meat grinding, meat filling, liquid filling, meat cutting, bottling, cereal punching, and packaging.

BALINT coatings have higher hardness and lower friction than soft stainless austenitic steel or hardened martensitic steel, which are typically used to reduce wear.

In addition, BALINT can be used effectively with sharp cutting edges, textured surfaces, or mirrored surfaces, as the coat thickness ranges from 0.5µm and 4µm.

FDA-approved coatings with a high surface hardness

There are a number of advantages to using BALINT surface technologies to protect your food processing equipment, including:

- BALINT coatings have a higher surface hardness and less particle abrasion, which makes cleaning easier

- Risks of galling is reduced due to the ceramic-like surface

- BALINT CROMA PLUS incorporates a wide variety of colours for a custom design

- The coatings have outstanding release properties against food polymers, giving long-lasting sharpness to punches and knives

- Coated components have excellent release and non-stick properties

- All BALINT coatings are US Food and Drug Administration (FDA) approved

About Oerlikon Balzers

Oerlikon Balzers is part of the surface solutions segment of Switzerland-based Oerlikon Group.

Engineered and assembled in Liechtenstein and Bergisch Gladbach, Germany, more than 1,100 of Oerlikon Balzers’ coating systems are in operation worldwide.

The company operates a dynamic network of more than 100 coating centres in 35 countries in Europe, the Americas, and Asia.

Products and Services

Video

Related Projects

Press Release

Oerlikon has acquired DIARC Technology, a provider of surface engineering technologies and services in Finland.

Read moreFollowing last year’s commissioning of the first Oerlikon Balzers INUBIA I6 coating system at Nanogate, the two companies have agreed to work together to further establish Oerlikon Balzers’ embedded physical vapour deposition (ePD) technology and develop new applications.

Read moreOerlikon Balzers gave a ground-breaking, innovative performance of BALIQ coatings, which are now available in a stunning range of colours with BALIQ UNIQUE.

Read moreOerlikon has signed an agreement to acquire Primateria, a provider of surface engineering services in Sweden.

Read moreRegional Offices

Iramali 18

LI-9496 Balzers

Liechtenstein