TNO Identification and Prevention of Microbiological Issues in Food Production

TNO is an independent research organisation with a wide diversity of expertise and research facilities. Innovation with purpose is what TNO stands for. We develop knowledge not for its own sake but for practical application: to create new products that make life more pleasant and valuable and help companies innovate; to find creative answers to the questions posed by society.

Food and microbial technology

The food industry faces various challenges affecting food safety and quality. Changing consumer demands, raw materials with fluctuating quality, new emerging food pathogens, and the changing scale of production, can all influence the microbiological status of the (end-) product.

These challenges require adequate tools. TNO offers the industry and community tailor-made solutions to address and prevent these complex microbiological issues.

We apply the tools and theory of genomics and molecular biology to generate insights into the physiology and ecology of microbes and microbial communities in the food production chain, and develop more efficient and safe food production and preservation technologies.

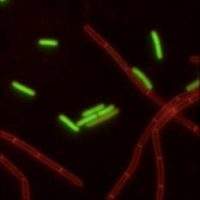

The application of state-of-the-art DNA sequencing technology allows us to rapidly determine community composition of various ‘food associated microbial ecosystems’ and characterise complete genomes of microbial isolates. For example, we have sequenced the genomes of several food-born pathogens and were able to make quantitative risk assessments based on genomic features that are involved in virulence, biofilm formation and antibiotic resistance.

Culture-independent analysis of the dynamics of microbial populations

TNO performs culture-independent analysis of the dynamics of microbial populations. This includes:

- Identification of microbiological effects of food processing changes (drinking water, ingredients, hygiene)

- Early warning and prediction of changes with respect to microbial quality and safety of products (food, feed, fermentation products)

- Identification of microbiological causes of quality deviations

Characterisation and identification of microorganisms

TNO’s capabilities in the characterisation and identification of microorganisms include: the rapid identification of microbial outbreaks of illness allowing support of subsequent measures (detection, tracing, intervention); source tracking and tracing; prediction of microbial behavior in processing; and strain selection for microbial productions and/or probiotics.

Rapid sensitive detection systems for specific pathogens and spoilage organisms

TNO employs rapid sensitive detection systems for specific pathogens and spoilage organisms. These new technologies are designed to improve QC-lab and service performance and reduce detection time. They are quickly replacing conventional culture-dependent microbiological analysis with improved culture independent methodology. They provide quantitative screening of shelf-life effects resulting from changes in product formulation.

Prognostic viability detection systems

Prognostic viability detection systems are new technologies for cleaning and disinfection. They improve hygiene testing and hygiene prediction and enable knowledge-based reduction of cleaning, allowing prolonged production runs.

Molecular sensors for monitoring functionality of physical, chemical and biological interventions

TNO uses molecular sensors based on microorganisms for monitoring the functionality of physical, chemical and biological interventions. These are used for:

- Screening novel natural antimicrobial compounds

- Screening for improvement of preservation strategies and technologies

- Screening disinfection activities

- Genotoxicity assay

- Antibiotics assay

- Shelf life prediction

- Optimisation of fermentation processes

- Viability assays

Products and Services

Video

Related Projects

Press Release

On 15 November TNO will open a new research facility at its Eindhoven location, the TNO Drying Facility. The setup has been especially designed for research activities in the area of droplet generation and drying, as well as powder production.

Read moreTNO's rapid and culture independent Campylobacter test offers hope to the Dutch poultry slaughter industry.

Read moreRegional Offices

Utrechtseweg 48

NL-3704 HE Zeist

Netherlands